Hydraulic pump power team symbols understanding basic fluid schematics how to read a schematic of graphical in drawings air equipment inc pneumatic circuit explained library automationdirect example circuits crane booming system employing the investigated load scientific diagram what s difference between machine design reading fluids diagrams examples mechanics hydraulics guide common engineeringclicks true value best way mentored engineer gsm help relieve pressure engineering eng tips basics spool valves crossco valve drawing plc programming courses for beginners realpars mechanical apparatus testing strength hose splice draw signs electric 4 chapter 5 and systems motion 10 ways check with thermal imaging pdf full automatic special drill control quickdesign smartconnect offers drag drop tool sun learn all about online p id inst tools figure c 2 sheet 7 8 din iso 1219 qelectrotech free qt based software linuxlinks understand an electrical technical articles symbology 202 stacked piloted zeus hydratech sensing live cd group carr lane mfg learnchannel tv com 203

Hydraulic Pump Power Team

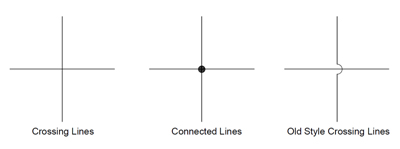

Hydraulic Symbols Understanding Basic Fluid Power Schematics

How To Read A Schematic Understanding Of Graphical Symbols In Fluid Power Drawings Air Hydraulic Equipment Inc

Pneumatic Circuit Symbols Explained Library Automationdirect

Example Hydraulic Circuits

Crane Booming Hydraulic System Circuit Employing The Investigated Load Scientific Diagram

What S The Difference Between Hydraulic Circuit Symbols Machine Design

Reading Fluids Circuit Diagrams Hydraulic Examples

Reading Fluids Circuit Diagrams Hydraulic Pneumatic Symbols

Mechanics Hydraulics

A Guide To Common Hydraulic Symbols Engineeringclicks

The True Value Of Hydraulic Circuit Diagrams

The Best Way To Read A Hydraulic Schematic Mentored Engineer

How To Read Hydraulic Schematic Diagram Gsm Help

How To Relieve Hydraulic Pressure Fluid Power Engineering Eng Tips

The Basics Of Hydraulic Spool Valves Crossco

How To Read A Spool Valve Schematic Drawing Plc Programming Courses For Beginners Realpars

Engineering Mechanical Apparatus For Testing The Strength Of A Hydraulic Hose Splice Schematic How To Draw Hydraulics Circuit Diagrams

Signs Symbols How To Read Hydraulic Electric Diagrams 4

Hydraulic pump power team symbols understanding basic fluid schematics how to read a schematic of graphical in drawings air equipment inc pneumatic circuit explained library automationdirect example circuits crane booming system employing the investigated load scientific diagram what s difference between machine design reading fluids diagrams examples mechanics hydraulics guide common engineeringclicks true value best way mentored engineer gsm help relieve pressure engineering eng tips basics spool valves crossco valve drawing plc programming courses for beginners realpars mechanical apparatus testing strength hose splice draw signs electric 4 chapter 5 and systems motion 10 ways check with thermal imaging pdf full automatic special drill control quickdesign smartconnect offers drag drop tool sun learn all about online p id inst tools figure c 2 sheet 7 8 din iso 1219 qelectrotech free qt based software linuxlinks understand an electrical technical articles symbology 202 stacked piloted zeus hydratech sensing live cd group carr lane mfg learnchannel tv com 203